Step-by-Step Process

Bio-CNG Production Flow

Complete breakdown of each stage in the Bio-CNG production process

Energy Crops+ Agri-Waste

Napier Grass + Cow Dung

Digester

Anaerobic digestion

Purification

Biogas to CBG

CBG Output

Ready for use

Bio-CNG Production Technologies

Three proven digestion technologies — each optimized for specific feedstock types, operating conditions, and commercial requirements

CSTR

Continuous Stirred Tank Reactor

Wet anaerobic digestion with continuous stirring for homogeneous feedstock

- Most bankable

- Proven technology

- Medium-large scale

HLR

High Rate / High Load Digestion

Fast digestion for high COD industrial waste with superior gas yield

- Highest returns

- Smaller footprint

- Industrial waste

Dry Digestion

Dry Anaerobic Digestion

Low water requirement system for high-solid feedstock and MSW

- Water-scarce regions

- High TS content

- MSW & agri-residue

Bio-CNG (CBG) – Industry Standard Specifications

Meeting international quality standards for compressed biogas

kJ/kg

Complete Bio-CNG Ecosystem

From feedstock sourcing to offtake agreements and government support — explore the complete value chain

Feedstock

Selecting the right organic feedstock is crucial for optimal plant design and performance.

-

Agricultural Residue — Rice straw, wheat straw, bagasse

-

Cattle Dung & Slurry — From dairy farms

-

Food & Market Waste — Organic MSW

-

Industrial Organics — Press mud, distillery waste

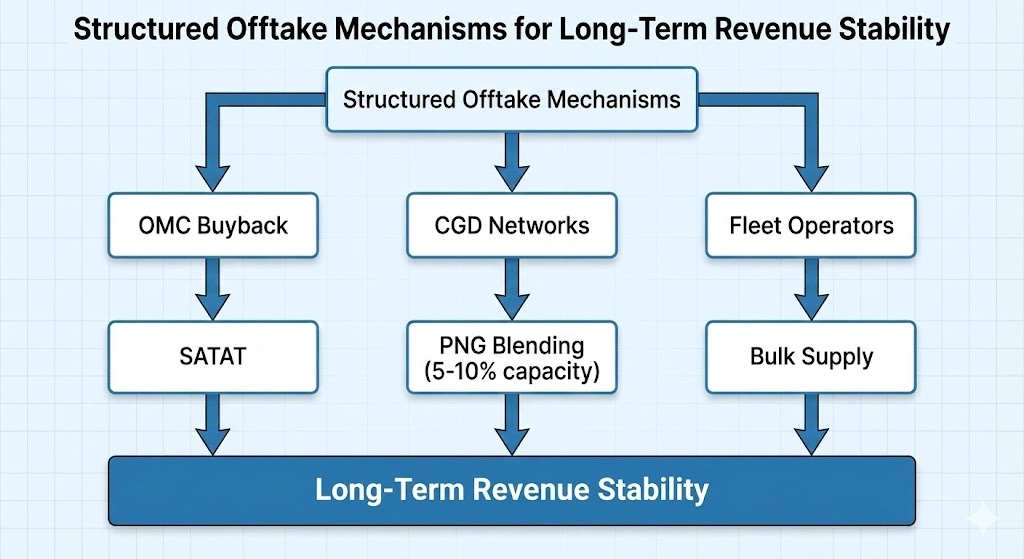

Buyback & Offtake

Structured offtake mechanisms ensuring long-term revenue stability through OMCs, CGD networks, and fleet operators.

Government Schemes

India's commitment to clean energy has created a favorable ecosystem for Bio-CNG development.

-

SATAT Framework — Guaranteed offtake

-

GOBARdhan Mission — Waste-to-wealth

-

Capital Subsidies — 30-40% support

Policy Advantages

Bio-CNG projects benefit from comprehensive government support, including subsidies, priority approvals, and long-term offtake guarantees under various national and state-level initiatives.

India's commitment to clean energy and waste management has created a favorable ecosystem for Bio-CNG development with strong policy backing and financial incentives.

Key Support Mechanisms

Scheme & state dependent financial support

Government facilitated resource access

Green financing & concessional rates

Additional revenue & ESG compliance

Streamlined clearances in select states

Long-term purchase agreements

When to Choose Which Technology

Technology selection guide based on climate, feedstock, water availability, and commercial objectives

| Decision Area | CSTR (Wet Digestion) | HLR / High-Rate Digestion | Dry Digestion |

|---|---|---|---|

| Best Climate Fit | Moderate to warm climates | Warm to hot climates | Cold, arid & variable climates |

| Why | Stable microbial activity, easy temperature control | Performs best at higher temperatures with fast kinetics | Low sensitivity to ambient temperature |

| Water Requirement | High | Medium–High | Very Low |

| Why | Requires slurry formation for digestion | High organic loading still needs dilution | Designed for high-solid feedstock |

| Ideal Feedstock | Cattle dung, slurry, mixed agri waste | Food waste, press mud, industrial organics | Straw, husk, agri residue, segregated MSW |

| Why | Homogeneous feedstock ensures process stability | High COD waste gives superior gas yield | Handles fibrous, high-TS solids efficiently |

| Best Commercial Use Case | Mixed agri-dung based projects | Industrial, clustered organic waste | MSW & agri-residue heavy regions |

| Why | Safest & most bankable | Highest returns at scale | Best for water-scarce & solid waste projects |

Best Climate Fit

Moderate to warm climates

Why: Stable microbial activity, easy temperature control

Warm to hot climates

Why: Performs best at higher temperatures with fast kinetics

Cold, arid & variable climates

Why: Low sensitivity to ambient temperature

Bio-CNG vs Conventional Fuels

Compare Bio-CNG with traditional fuel alternatives across key performance and sustainability metrics

| Fuel Type | Cost per Unit | Chemical Composition | Emissions | Typical Usage |

|---|---|---|---|---|

|

Bio-CNG (CBG)

|

₹48-55/kg | 92-98% CH₄ | Carbon Neutral | Vehicles, Industries, PNG blending |

| Fossil CNG | ₹70-85/kg | 85-95% CH₄ | High Carbon | Vehicles, Industries |

| LPG | ₹90-110/kg | Propane/Butane | High Carbon | Domestic, Commercial |

| Diesel | ₹95-100/L | Hydrocarbon mix | Very High | Transportation, Generators |

| Furnace Oil | ₹55-65/L | Heavy petroleum | Very High | Industrial heating |

| PNG | ₹40-50/kg | 80-90% CH₄ | High Carbon | Domestic, Commercial |

Bio-CNG (CBG)

Vehicles, Industries, PNG blending

Why Hastus Energy

Your trusted partner for Bio-CNG plant development and operation

Multi-Technology Capability

CSTR, HLR, and Dry Digestion expertise under one roof. We help you select the right technology based on your feedstock, climate, and commercial objectives.

End-to-End EPC Execution

Complete project delivery from feasibility study to commissioning. Engineering, procurement, construction, and long-term O&M support.

Global Pan-India Experience

50+ successfully delivered Bio-CNG projects across 15+ states in India and international markets. Proven track record in diverse conditions.

Your Bio-CNG Partner

Planning a Bio-CNG Plant?

Get the right technology, feedstock strategy, machinery sizing, and execution partner — all under one roof.

Complete Solutions

From concept to commissioning

Hastus Energy - Leading Bio-CNG Technology Provider in India