What are Biomass Pellets?

Biomass pellets are compressed organic materials derived from agricultural residues, wood waste, and energy crops. These cylindrical pellets represent a sustainable and renewable energy source that can replace fossil fuels in various applications. Learn about our biomass pellet manufacturing services.

Manufactured through a process of densification, biomass pellets offer high energy density, low moisture content, and consistent quality. They are carbon-neutral, as the CO₂ released during combustion is equal to what the plants absorbed during growth, making them an environmentally friendly alternative to conventional fuels. Biomass pellets contribute to carbon credit generation.

With applications ranging from industrial heating to residential cooking and power generation, biomass pellets contribute significantly to reducing greenhouse gas emissions while promoting sustainable waste management and rural economic development. These projects create sustainable rural employment opportunities.

Raw Material

Hammer Mill (For Particle Size Reduction)

Dryer (For Moisture Reduction)

Pellet Mill

Cooling & Packaging

Biomass Pellets

Biomass Pellet Production Process

Our biomass pellet plants transform agricultural residue into high-density energy pellets for industrial & commercial applications.

Biomass Pellets – Industry Standard Specifications

Meeting international quality standards for biomass pellets

10-12mm (industrial)

10-20% (agri)

kcal/kg

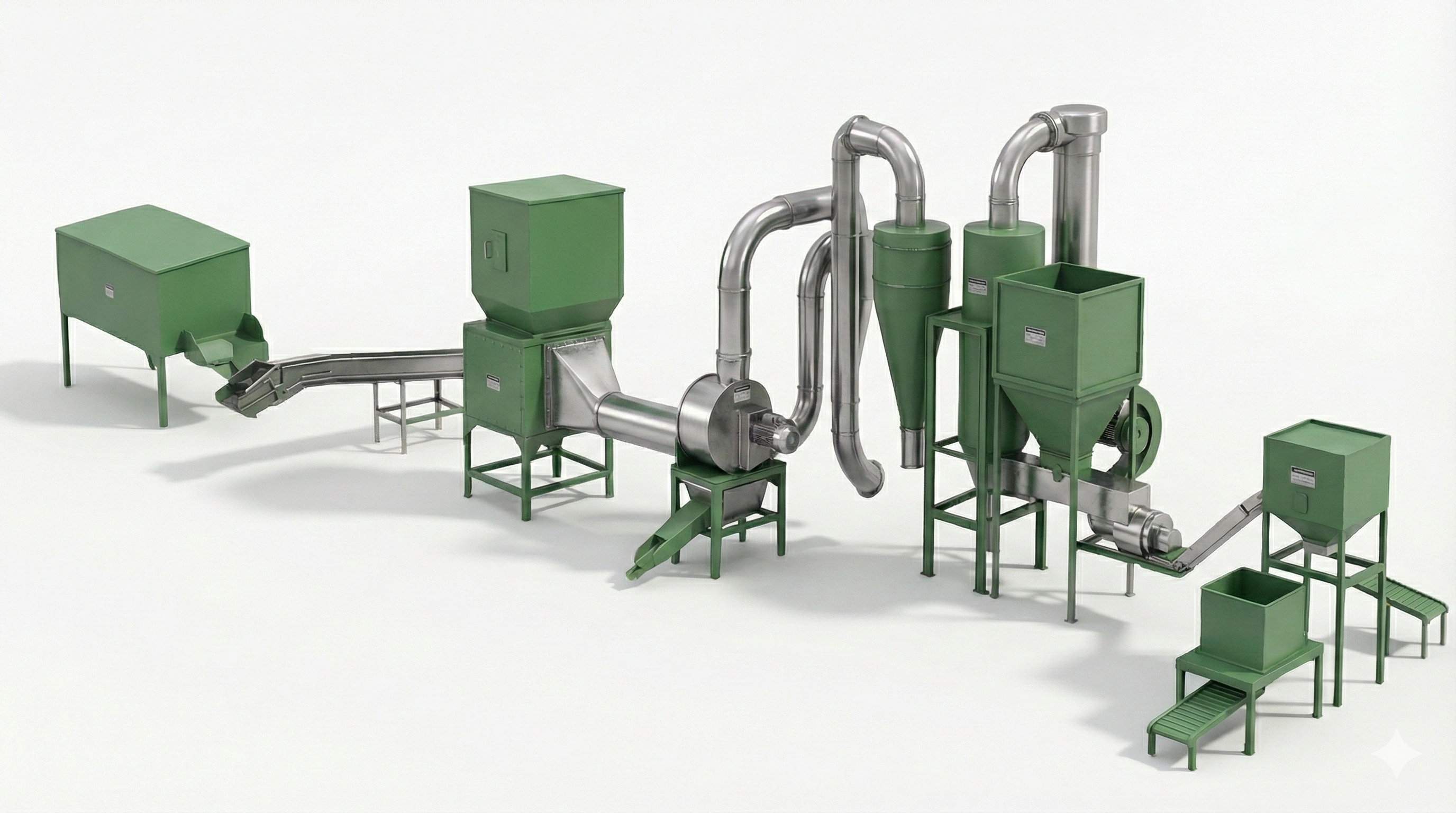

Equipments for Pellets

Auto Feeding Unit

Automated material handling system that continuously feeds raw biomass into the processing line with controlled flow rate and uniform distribution.

- Types Available: Vibratory Feeder, Screw Feeder, Belt Feeder, Pneumatic Feeder

- Capacity: 500kg/hr, 1TPH, 2TPH, 5TPH

- Power: 2-15 kW

- Feed rate: Adjustable 0-100%

- Control: Manual, Semi-automatic, Fully automatic with PLC

- Features: Level sensor, Flow control, Emergency stop, Material flow monitoring

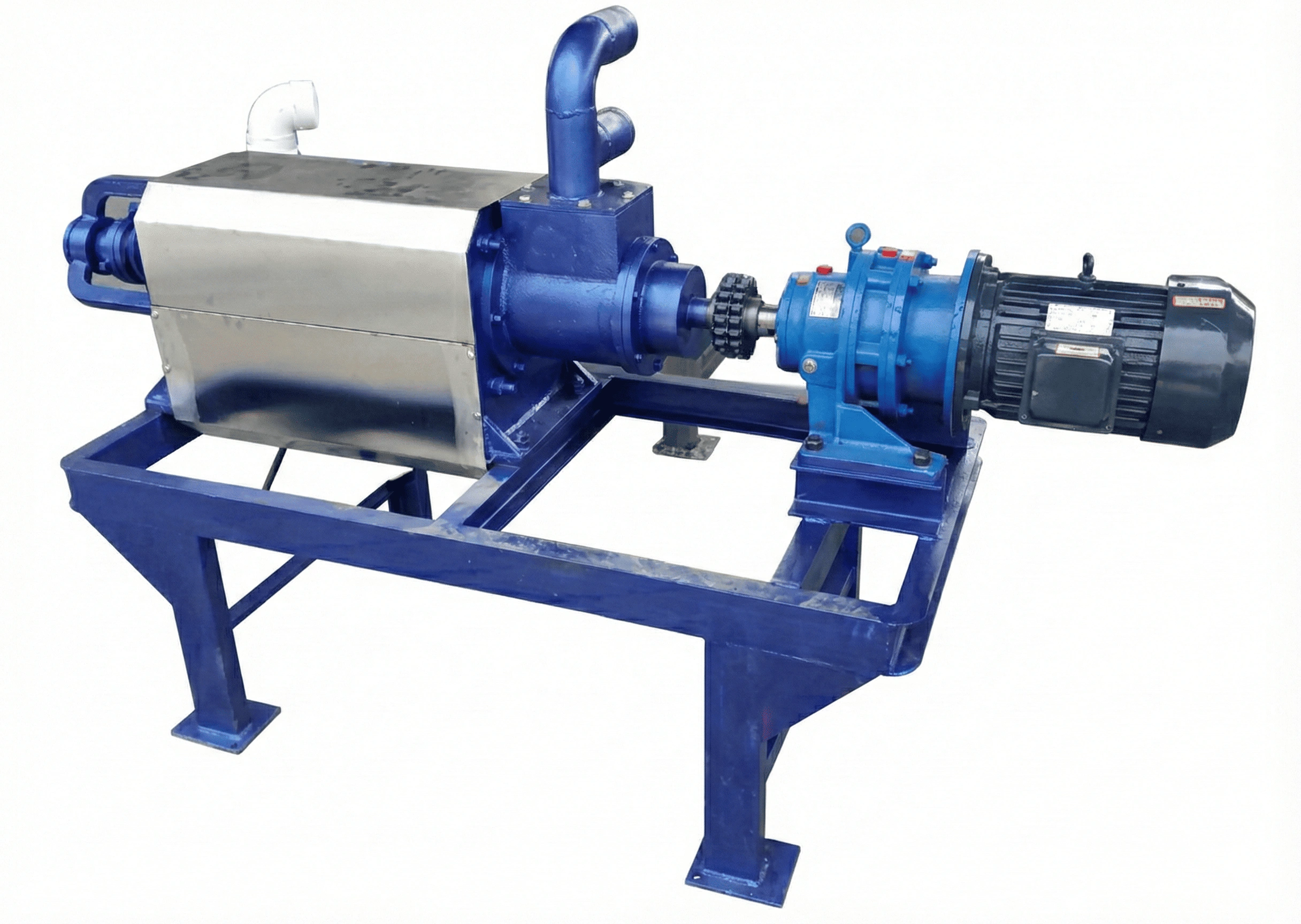

Dewatering System

Removes excess water from wet biomass material before processing to reduce moisture content and improve efficiency.

- Types Available: Screw Press, Belt Press, Centrifuge, Filter Press

- Capacity: 1TPH, 2TPH, 5TPH, 10TPH

- Power: 10-50 kW

- Moisture reduction: 40-60% to 20-30%

- Features: Continuous operation, Automatic discharge, Adjustable pressure

Solid Liquid Separator

Separates solid biomass from liquid slurry to prepare material for pelletization process.

- Types Available: Screw Press Separator, Centrifugal Separator, Belt Filter Press

- Capacity: 1TPH, 2TPH, 5TPH

- Power: 5-30 kW

- Separation efficiency: 85-95%

- Solid content output: 20-40%

- Features: Continuous operation, Automatic discharge, Easy maintenance

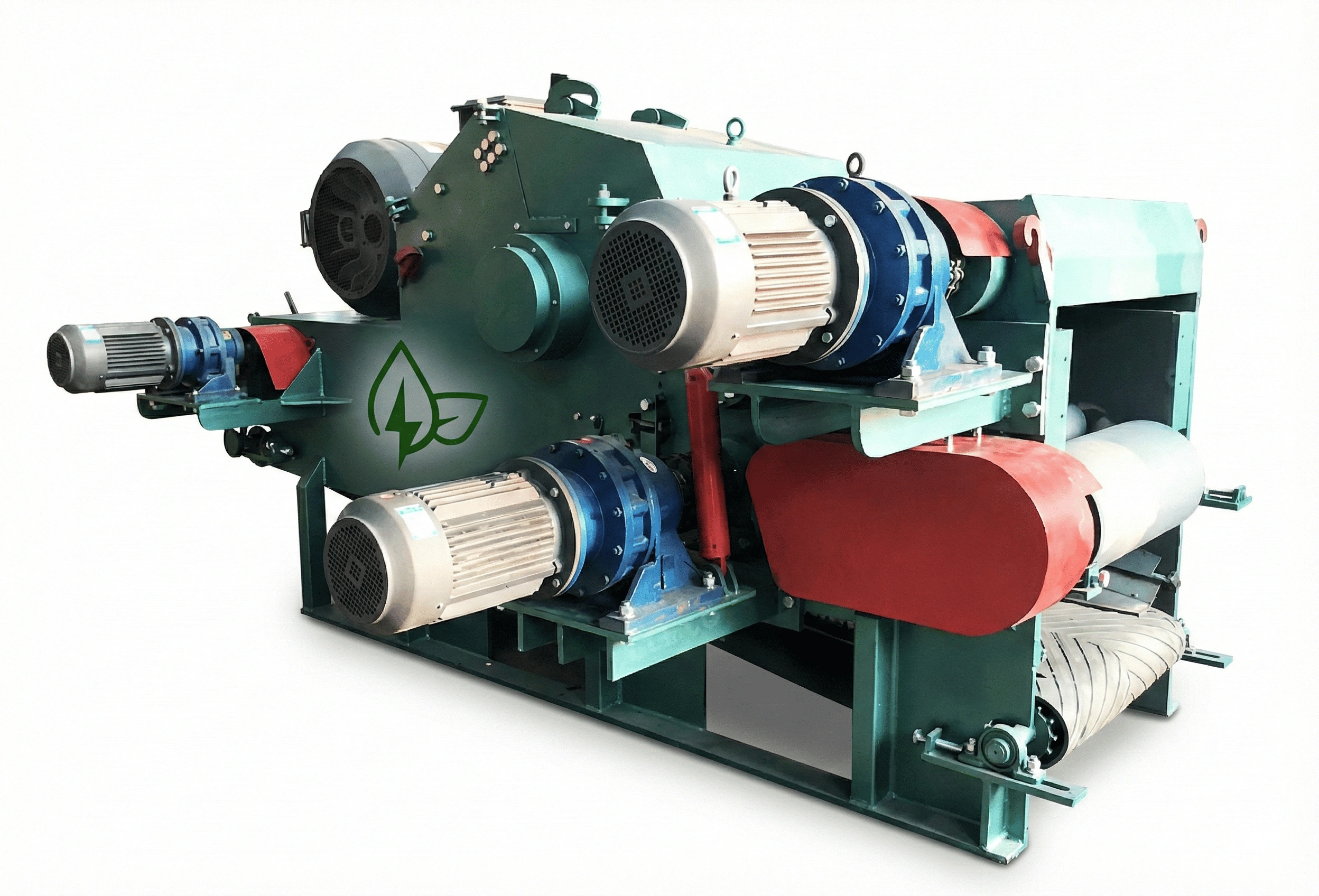

Chipper

Cuts large wood pieces and biomass into smaller chips for easier processing and handling.

- Types Available: Disc Chipper, Drum Chipper, Knife Chipper

- Capacity: 500kg/hr, 1TPH, 2TPH, 5TPH

- Power: 15-75 kW

- Feed size: up to 300mm diameter

- Output size: 10-50mm chips

- Features: Adjustable chip size, Auto-feed system, Safety guards

Dryer (Rotary/Flash/Belt Dryer)

Reduces moisture content in raw biomass from 40-60% to optimal 10-15% for pelletization.

- Types Available: Rotary Drum, Flash, Belt, Fluidized Bed

- Capacity: 500kg/hr, 1TPH, 2TPH, 5TPH

- Power: 20-150 kW

- Moisture removal: 200-1000 kg/hr

- Inlet temp: 300-600°C | Outlet temp: 80-120°C

- Efficiency: 70-85%

Shredder

Initial size reduction of raw biomass material to prepare it for further processing and grinding.

- Types Available: Single Shaft, Double Shaft, Four Shaft, Industrial Shredder

- Capacity: 500kg/hr, 1TPH, 2TPH, 5TPH

- Power: 15-110 kW

- Feed size: up to 200mm

- Output size: 20-50mm

- Features: Adjustable screen size, Auto-reverse function

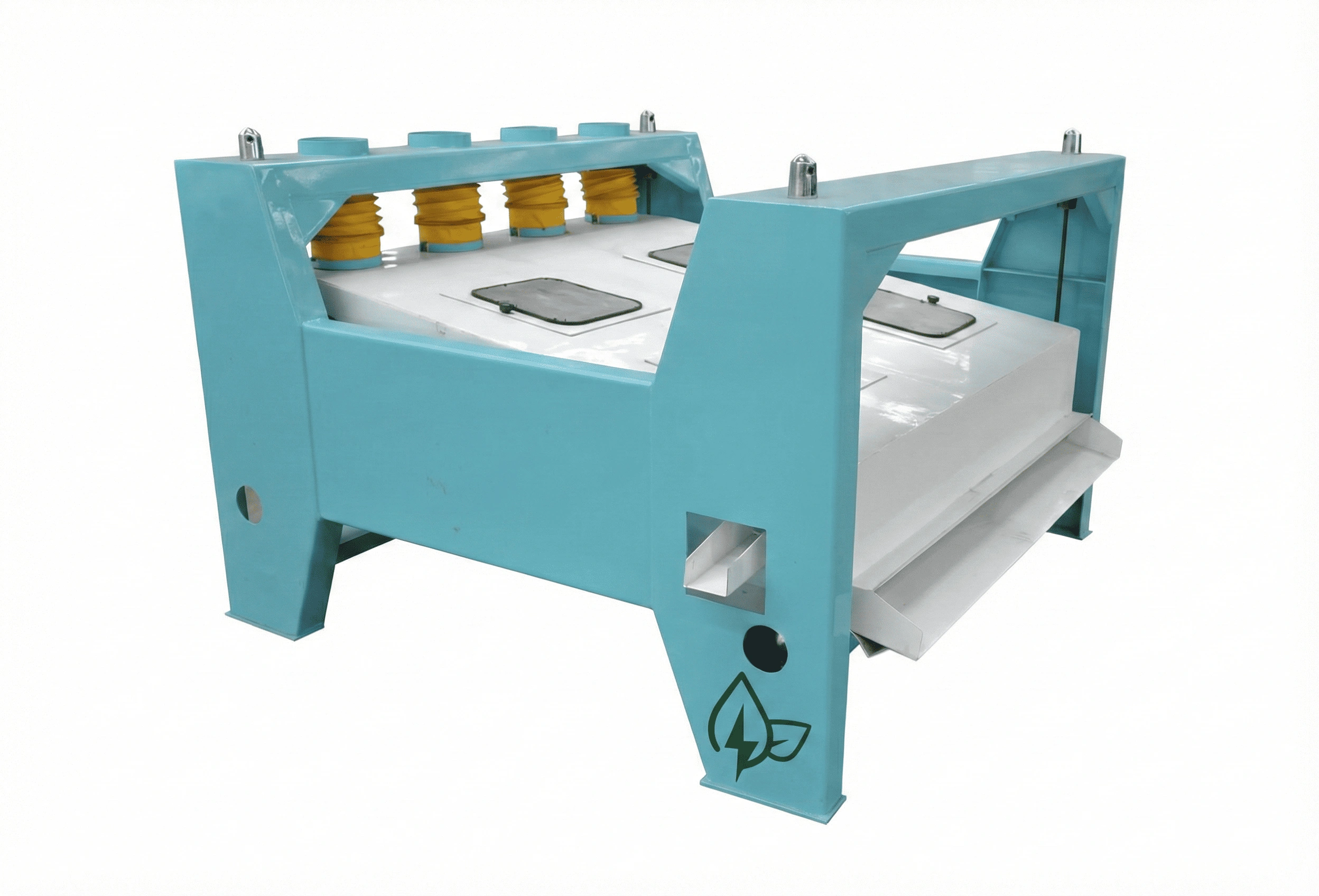

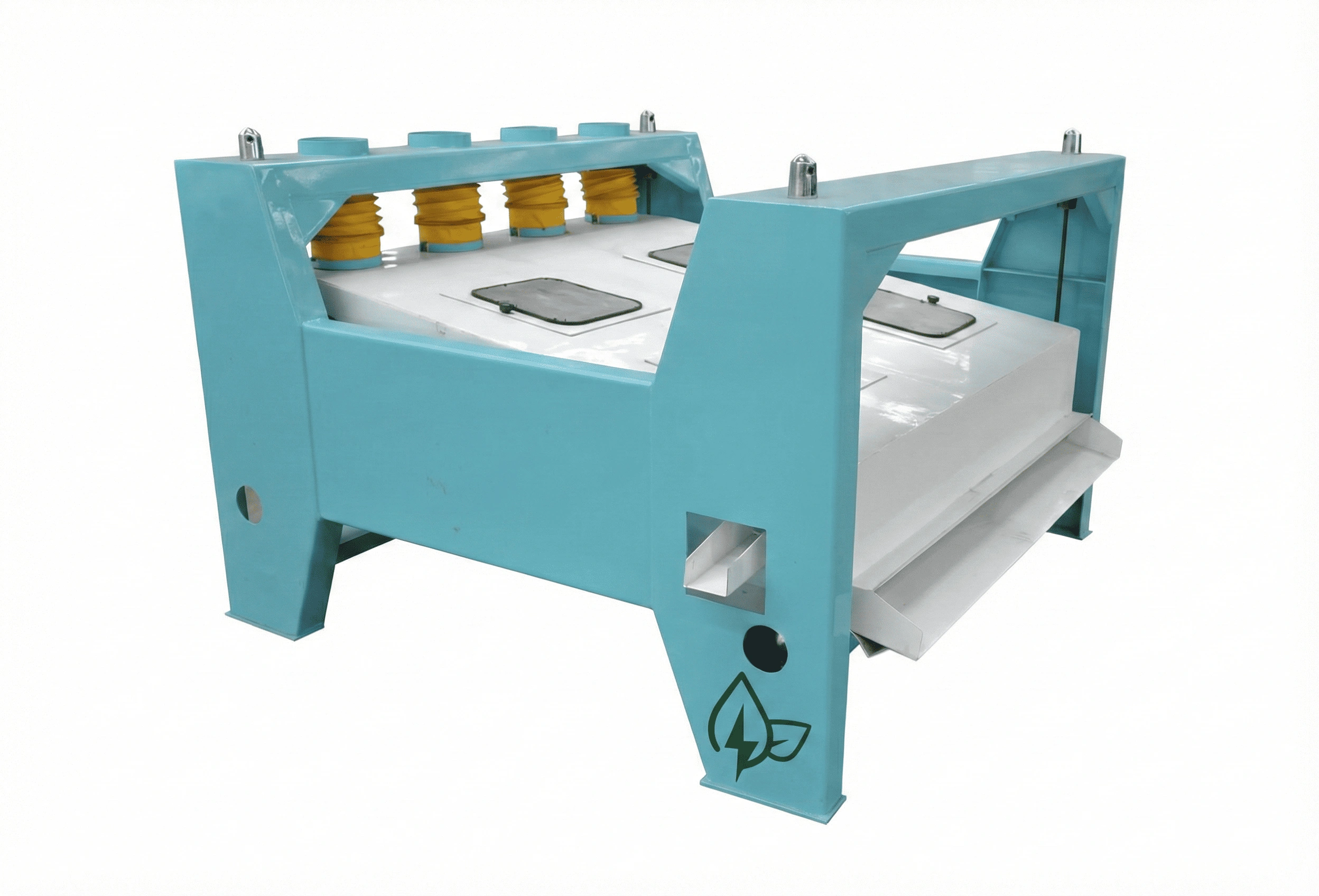

Siever

Screens and separates biomass material by size to ensure uniform particle distribution for pellet production.

- Types Available: Vibrating Sieve, Rotary Sieve, Trommel Screen

- Capacity: 1-10 TPH

- Power: 2-10 kW

- Screen sizes: 2mm, 4mm, 6mm, 8mm, 10mm

- Efficiency: >90%

- Features: Multi-deck screening, Easy screen replacement, Self-cleaning

Hammermill/Grinder

Reduces particle size of dried biomass to 3-5mm for uniform pellet quality.

- Types Available: Swing Hammermill, Fixed Hammermill, Pin Mill, Turbo Mill

- Capacity: 500kg/hr (15kW), 1TPH (37kW), 2TPH (75kW), 5TPH (150kW)

- Screen size: 3mm, 4mm, 5mm

- Feed size: up to 50mm

- Output: 80% <5mm

Pellet Mill

Core equipment that compresses ground biomass through die holes to form dense pellets.

- Types Available: Ring Die, Flat Die, Large Scale Industrial, Small Scale

- Ring Die: 1TPH (75kW), 2TPH (132kW), 3TPH (160kW), 5TPH (250kW)

- Flat Die: 100kg/hr (15kW), 300kg/hr (30kW)

- Die diameter: 300mm, 400mm, 500mm, 600mm

- Die hole: 6mm, 8mm, 10mm | Pressure: 100-200 bar

Pellet Cooler

Cools hot pellets from 80-90°C to ambient temperature and reduces moisture for storage stability.

- Types Available: Counter Flow, Horizontal, Vertical, Fluidized Bed

- Capacity: 1TPH, 2TPH, 3TPH, 5TPH

- Cooling time: 10-20 minutes

- Air flow: 1000-5000 m³/hr

- Outlet temp: 25-35°C

- Moisture reduction: 1-3%

Screening Machine/Vibrating Sieve

Separates fines and oversized pellets from finished product for quality control.

- Types Available: Rotary Sieve, Vibrating Screen, Drum Sieve, Two-deck Screen

- Capacity: 1-10 TPH

- Screen size: 4mm, 6mm, 8mm

- Efficiency: >95%

- Fines return: Auto recycling

- Motor: 1.5-5.5 kW

Siever

Screens and separates biomass material by size to ensure uniform particle distribution for pellet production.

- Types Available: Vibrating Sieve, Rotary Sieve, Trommel Screen

- Capacity: 1-10 TPH

- Power: 2-10 kW

- Screen sizes: 2mm, 4mm, 6mm, 8mm, 10mm

- Efficiency: >90%

- Features: Multi-deck screening, Easy screen replacement, Self-cleaning

Conveying System

Transports biomass material between different processing stages.

- Types Available: Belt, Screw, Bucket Elevator, Pneumatic, Chain Conveyor

- Belt: 5-50 TPH, length 5-50m

- Screw: 1-10 TPH, length 3-20m

- Bucket: 5-30 TPH, height 5-30m

- Incline: 0-45°

Storage Silo

Stores raw material and finished pellets in controlled environment.

- Types Available: Hopper Bottom, Flat Bottom, Steel, Concrete

- Capacity: 10 ton, 25 ton, 50 ton, 100 ton, 500 ton

- Discharge: Pneumatic/Mechanical

- Features: Aeration system, Level indicator

Dust Collection System

Captures airborne dust particles from grinding and processing to ensure clean environment.

- Types Available: Bag Filter/Bag House, Cyclone Separator, Wet Scrubber, Electrostatic Precipitator

- Air flow: 1000-10000 m³/hr

- Efficiency: 95-99.5%

- Power: 5-30 kW

- Filtration: <5mg/Nm³

- Features: Auto pulse cleaning

Crumbler/Pellet Crusher

Recycles oversized or defective pellets back into the production process.

- Types Available: Roll Crusher, Rotary Crusher, Hammer Crusher

- Capacity: 500kg/hr - 2TPH

- Power: 5-15 kW

- Output size: 3-5mm

Control Panel & Automation

Centralized electrical control and automation of pellet production line.

- Types Available: Manual Control Panel, Semi-automatic PLC, Fully Automatic SCADA

- Components: Motor starters, VFD, PLC, HMI

- Features: Emergency stop, Temperature monitoring, Production monitoring, Remote control option

Electric Unit

Power distribution and electrical control system for the entire pellet production plant.

- Components: Main Distribution Panel, Motor Control Centers, Transformers, Switchgear

- Power rating: 100kW - 500kW

- Voltage: 415V, 3-phase, 50Hz

- Protection: Overload, Short circuit, Earth fault protection

- Features: Power factor correction, Energy monitoring, Safety interlocks

Common Biomass Materials

Napier Grass

Fibrous agricultural residue with moderate energy content used widely in biomass production.

Parali (Paddy Straw)

Readily available crop residue offering balanced combustion efficiency and easy pelletization.

Wooden Chips

Woody biomass feedstock with excellent heating value and low ash content for cleaner burning.

Explore Our Complete Feedstock Library

Discover 42+ sustainable feedstocks for biomass pellet production. Compare ash content, heat values, and quantity requirements for all materials in our comprehensive library.

View Feedstock Library