Understanding CBG Cascades and Storage Systems

A look inside the backbone of Bio-CNG logistics — cascades that store, transport, and stabilize green energy delivery.

Read Article →From anaerobic digesters to purification skids — discover the tech engines powering India's Bio-CNG movement.

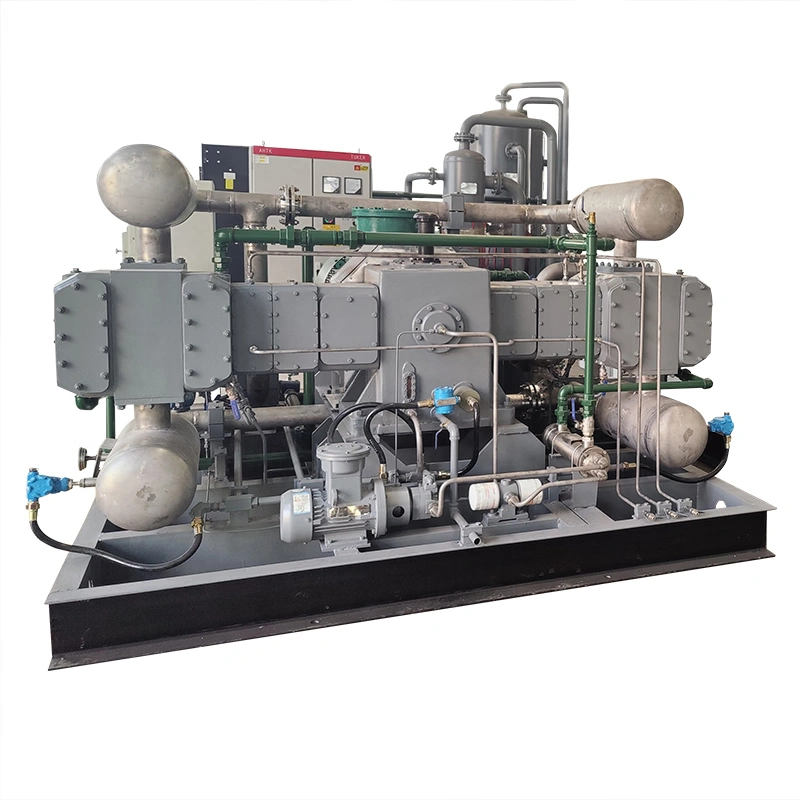

The Bio-CNG revolution rests on innovation — in biogas purification, upgrading, and compression technologies. Each stage converts organic waste into clean, usable fuel.

Organic feedstock like press mud, Napier grass, and food waste undergo microbial breakdown in oxygen-free digesters, producing raw biogas rich in methane (55–60%).

Advanced systems like water scrubbing, PSA (Pressure Swing Adsorption), and membrane separation remove CO₂, H₂S, and moisture, yielding >96% pure methane gas.

After upgrading, CBG is compressed up to 250 bar and stored in cascades for easy dispatch.

IoT-enabled PLCs and SCADA interfaces monitor plant operations, safety, and energy balance in real time.

Hastus Insight: The shift toward automated, modular CBG plants is redefining the scalability of India's rural clean energy infrastructure.

Stay informed with the latest insights on renewable energy, Bio-CNG, and sustainable solutions.